Applying Machine Learning to Manufacturing

An employee inspects a jet engine at the Rolls Royce's Mechanical Testing Operations Centre in Blankenfelde-Mahlow near Berlin.

Photo: Odd Andersen/AFP/Getty Images

If manufacturers want to sustain and grow their customer bases in a competitive environment, their products need to fulfill increasingly high quality and reliability standards. Automakers, for example, now have a target defect rate for the integrated systems of less than 1 percent. That’s putting pressure on the original equipment makers (OEMs) and their suppliers who have to meet these targets at the same time that products and manufacturing processes are becoming increasingly complex and featuring numerous activities that impact quality, performance, and yield. To prevent failures of components, systems, and ultimately the product, these manufacturers need reliable methods to find defects.

But quality control today is, in many cases, still performed by human inspectors, which limits its reliability and efficiency. Components such as turbine blades and welded joints are highly safety-critical, and their manufacturers typically perform quality inspection with systems such as 3-D CT scanning that produces images in 100 or more layers. Inspectors then examine each of these for possible defects, such as porosity or shrinkage. But it’s often difficult for people to distinguish correctly between a defect and image noise—random variations of brightness or color caused by something other than the object being examined. Some inspectors may be less skilled than others, and any inspector is subject to human error. As a result, complex defects can be either missed or detected very late in the manufacturing process. This lowers yield, increases the amount of rework needed, and can even lead to field failures.

A New Era for Quality Control

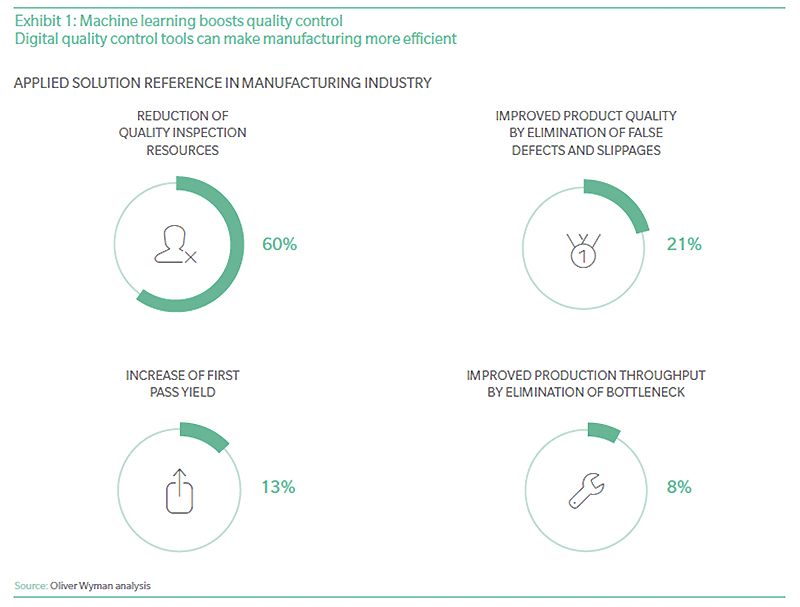

Advanced analytics based on the exploitation of big data provides an innovative approach for digital quality management. In machine learning, a neural network generalizes historical quality-control data and thus learns to identify defects such as porosities in casted parts. It also learns to ignore other structures that arise from things such as complex geometry and image noise, which might look like defects, but are not. The system can thus predict quality-critical deviations with a high degree of accuracy. These insights are used to improve practices and to predict outcomes and interactions. In one case, a digital quality control system based on machine learning reduced the number of quality inspectors for a safety-critical component by 60 percent, while also reducing the risk of false defect detection and defect slippage by 21 percent.

However, many engineering and manufacturing companies face difficulties leveraging advanced analytics in technical products and processes. Some may not fully leverage the data they already have. Or they invest in data-warehousing programs that do not fit their manufacturing processes. Others lack the means to extract information that reveals essential correlations and characteristics in a system or process.

There are numerous benefits for those that can implement an innovative, advanced quality-management system. Automated digital quality inspection provides early warning of any shift in production processes; it helps uncover the root causes of problems and enables engineering improvements; and it reduces the risk of shipping nonconforming parts. As a result, it helps prevent product failure and reduces the costs of substandard quality. Ultimately, this will lead to lower warranty costs and greater customer trust in a firm’s products (see Exhibit 1).

As the era of digital manufacturing arrives, advanced analytics will be a critical tool for realizing improvements in yield, particularly in areas with product and process complexity, process variability, and capacity limitations. Manufacturing companies that successfully apply the new tools have an opportunity to set themselves apart from their competitors and generate additional value.

This piece first appeared in Perspectives on Manufacturing Industries, vol. 11, Oliver Wyman.