Will China’s COVID Policy Revision Disrupt Global Supply Chains for Critical Technologies?

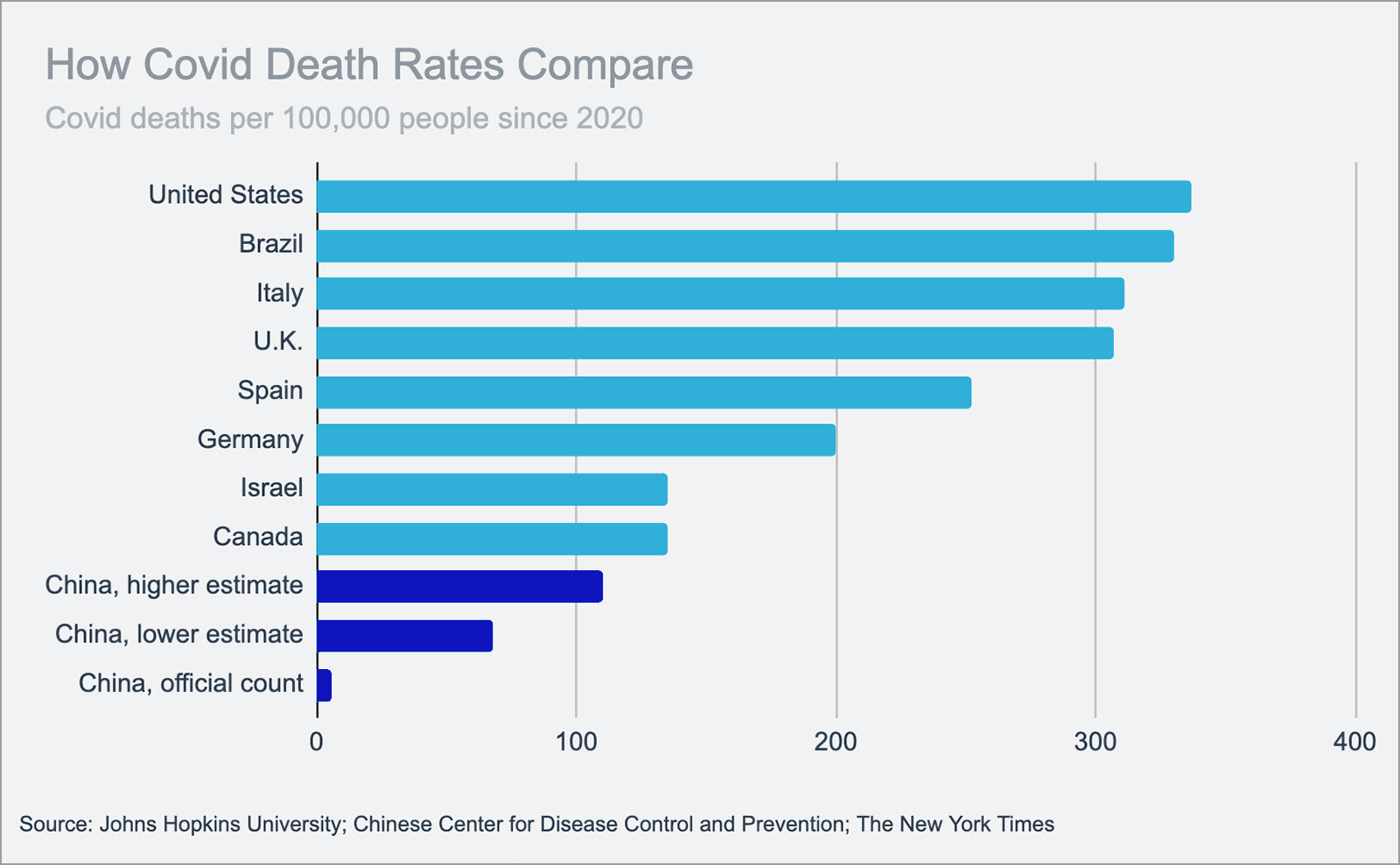

With China lifting its “zero-COVID” measures late last year, epidemiologists from China’s Center for Disease Control and Prevention (CDC) estimate that at least 80% of the population has been infected since December 2022, impacting manufacturing operations significantly. Consequently, production backlogs and an increase in delivery times meant China’s manufacturing PMI score fell to 47% in December 2022, its lowest since the pandemic began. This led to increased supply chain pressure (which had already been rising since September 2022), as reflected on the GSCPI. This trend is likely to continue in the near term.

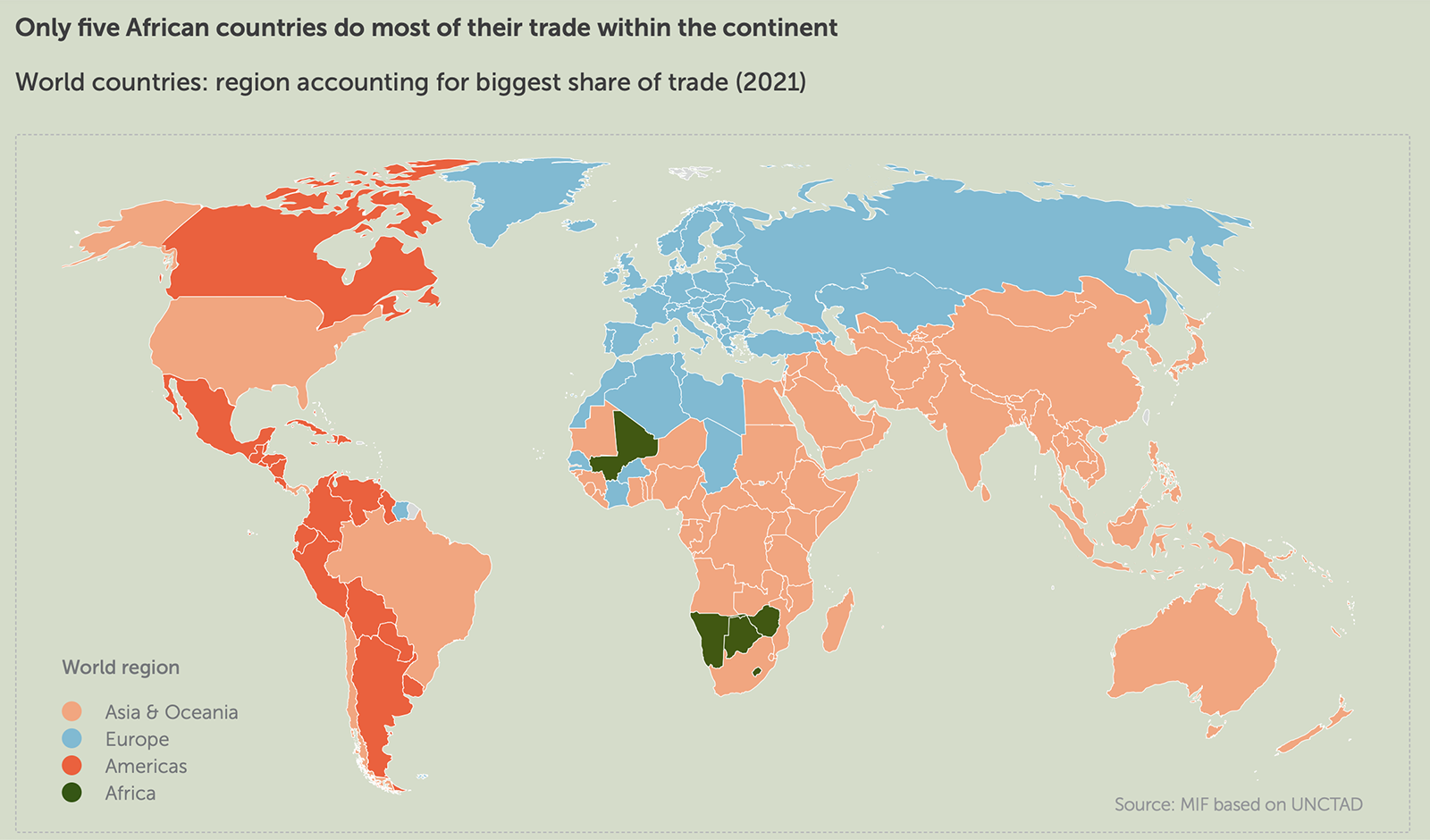

China’s leading market share and criticality to major technological sectors pose a dire challenge for companies looking to diversify production. Apple, for instance, might take about seven years to move 10% – 20% of its production capacity out of China. The IEA also estimates that the world will almost singularly rely on China to supply key building blocks for solar panel production through 2025. With limited capacity to shift production of key components away from China in the short-term, supply pressures for many products are expected to worsen in 2023.

With a second surge in cases expected in China’s secondary cities and rural regions after the Lunar New Year holidays, businesses globally need to remain vigilant as supply chain pressures continue to rise and the broader impact of the outbreak remains to be seen.